Improving DC EV Charger Maintenance with IR-Based C IR Indication

As electric vehicles (EVs) continue to gain popularity, the demand for fast and reliable charging infrastructure is surging. This has led to an increasing focus on ensuring that EV chargers, particularly DC fast chargers, operate efficiently and remain accessible to drivers during long journeys. One of the critical challenges in maintaining these charging stations is minimizing downtime caused by electrical failures, which can disrupt service and delay repairs. In this case study, we explore how ETI’s innovative C IR indication module provides a cutting-edge solution for monitoring and maintaining the electrical wiring within DC EV chargers, improving both reliability and maintenance efficiency.

1. Fast DC Chargers

Electric vehicles (EVs) are becoming more common, and with them, there is an increasing demand for reliable and accessible charging infrastructure.

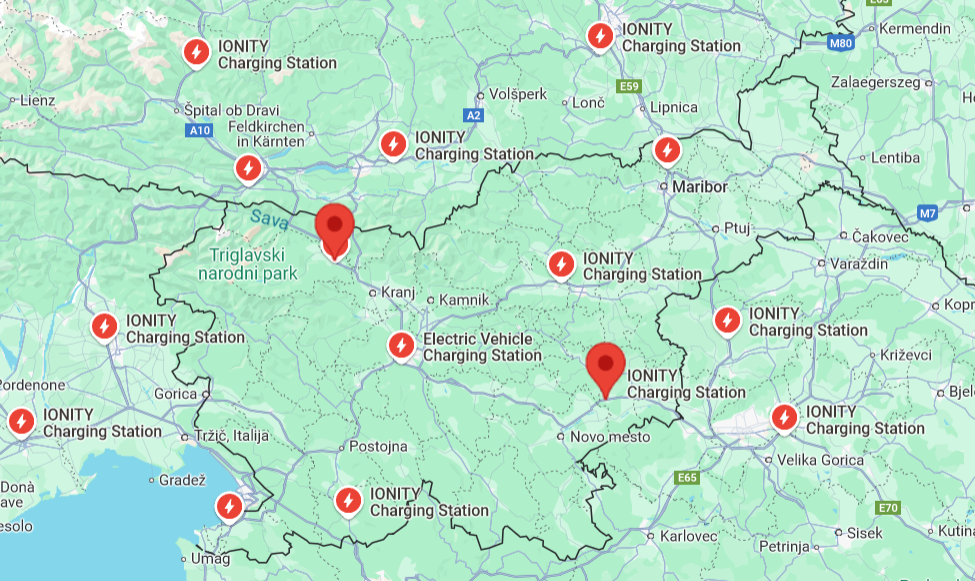

The main purpose of DC EV chargers is to quickly refill the EV battery during long journeys. Consequently, EV chargers are usually positioned along highways at existing petrol stations. The distance between EV charging stations can be considerable, and any failure in the electrical wiring results in an unexpected and unwanted shutdown of the charging station. Because of the long distances between stations, maintenance is more difficult, as it takes time for the maintenance team to reach the failed device. Any information regarding the potential failure is highly valued.

To avoid such incidents and to speed up maintenance time, the electrical wiring needs additional solutions for the indication of operated protection devices – fuse-links.

2. DC Charger electrical wiring

Inside a DC EV charging station, there are main and auxiliary electric circuits, each protected with cylindrical fuse-links installed in cylindrical fuse-disconnectors/holders (EFD/EFH). Each electric circuit is crucial for the uninterrupted and reliable operation of the charging station.

The DC charging station has its own hardware designed for power management and communication through the operator's user interface. The EV charger's electronic board enables communication at a distance, displaying actual data and parameters necessary for an optimal user experience. This communication allows operators to monitor the status of the charging station and detect any errors. Developers of electronic boards typically provide additional digital inputs that enable communication with other electric equipment that is not part of the electronic board but still belongs to the EV charger.

Figure 3: Free digital inputs enable communication with other devices that are a part of EV Charger

With these additional digital inputs, it is possible to connect indication devices that show the real-time status of devices within the EV charger. One such device is the indication of operated fuse-links.

3. C IR indication

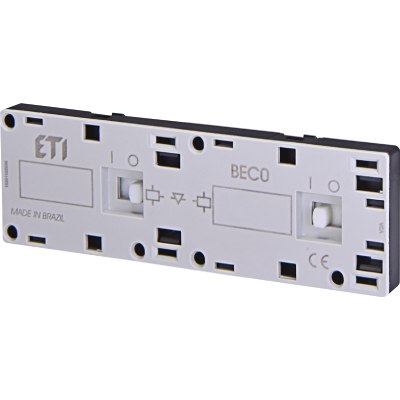

ETI introduces a new solution for fuse indication within cylindrical fuse disconnectors/holders (EFD/EFH) that directly communicates with the electronic board via digital inputs.

The new IR-indication enables remote monitoring of all cylindrical fuse disconnectors/holders. Its most important advantage is that it does not require fuse-links with striker indicators; it works with standard cylindrical fuse-links. Additionally, it supports sizes 8x32 and 10x38 fuse-links, making it the first and only solution for these sizes.

Figure 4: The wiring diagram of C IR indication modules

The C IR indication is also a space-saving solution, as it reduces the space required compared to traditional solutions that use auxiliary switches.

For the operation of the C IR indication, an LED-type cylindrical fuse disconnector/holder (EFD/EFH) in combination with the C IR module is required. The C IR modules can be wired either in series or in parallel, depending on the type of indication the designer desires (indication of each circuit separately or indication of a group of circuits).

4. C IR indication – Integration to EV charger

The C IR remote indication module detects operated fuse-links and generates a digital signal that can be linked to the EV charger's hardware. The EV charger’s electronic board connects to the gateway and, further on to the internet. This solution enables remote communication, allowing operators to monitor real-time information about each electric circuit inside the EV charging station. Such a system saves time when failures occur within the station.

Figure 5: Simplified picture of integrated C IR solution

5. Conclusions

The C IR indication module is a valuable solution for the fast detection of operated fuse-links within an EV charging station. With this solution, maintenance time is significantly reduced, as the team is better informed about the possible failure, enabling them to solve the issue more efficiently. This article presents the integration of the C IR solution with an EV charging station. A similar integration is possible with other applications such as PV inverters, industrial applications, or any device that supports communication via digital inputs. The C IR indication is a step forward in developing smart products that support digitalized solutions.