The new ETI HXS standing enclosures of the SOLID GSX System

The ETI's offer was expanded with new metal free-standing HXS300 and HXS400 cabinets, while a wide range of additional and indoor equipment greatly enhances the scope of the entire SOLID GSX system.

Advantages:

• High versatility and flexibility of configuration

• Quick assembly

• Three-point door locking system with toothed mechanism and lever with the option of being equipped with a system or patent insert

• Unscrewed rear wall with polyurethane poured gasket

• High-quality diaphragm glands from the top and double aluminum from the bottom

• Painted with polyester paint resistant to UV radiation

HXS system standing enclosures of the SOLID GSX series are available in three standard widths (550 mm, 800 mm, 1050 mm) and a depth of 300 mm (enclosure 1850 mm high) and 400 mm (enclosure with a height of 2000 mm). The enclosures have possibility to be equipped with mounting plates, internal sets with electric equipment and a power distribution system based on busbars.

It is possible to choose between empty enclosures and enclosures with a universal mounting plate already installed inside. Due to the dedicated mounting holes and weaknesses in the side walls, the enclosures can be connected one to another into sets. Cables or rail bridges can be mounted between sections. The enclosures can be attached to the wall using dedicated holes in the back wall or special wall holders. The enclosures can be also attached to the floor through holes in the plinths.

Possibility of any configuration

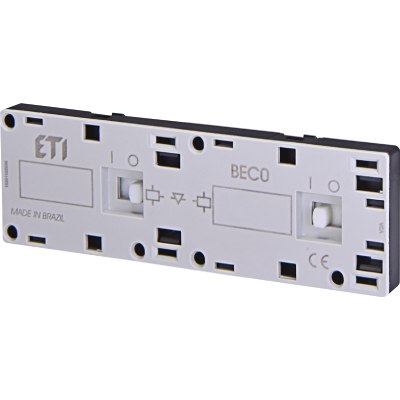

All SOLID GSX system housings have common internal equipment. CP covers, PM mounting plates or TH-S rails have standardized dimensions and methods of assembly. Those can be used in hermetic GT enclosures, 4XP160 flush-mounted, 4XN160 surface-mounted and in HXS standing enclosures.

A wide range of accessories ensures the possibility of adapting the enclosure equipment to individual requirements.

A wide range of dedicated covers and mounting plates allows for a significant reduction in the prefabrication time, the CP x-x PF covers with a plastic filling and PM-F universal mounting plates allow for the installation of non-standard equipment.

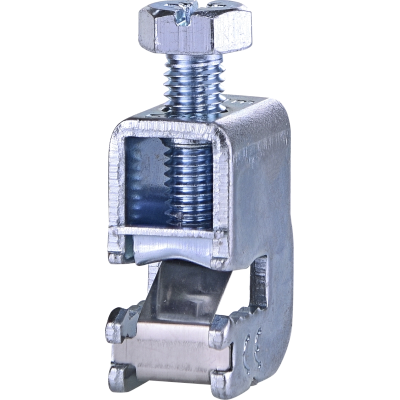

Solutions in HXS enclosures allow the mounting of busbars system directly on the back wall of the enclosure. This solution not only saves space but also greatly facilitates power distribution. Due to the maintenance of appropriate distances and the implementation of dedicated weaknesses in the side walls of the enclosures, it is possible to direct conductor bars between the enclosures connected in sets.

Well thought-out design solutions enable any configuration of HXS.

Construction solutions that facilitate installation

The common elements and similar solutions in the entire SOLID GSX system significantly facilitate the assembly and prefabrication of switchgears.

The same screws and bolts allow for less frequent tool changes. Moreover many small positioning details and markers shorten the assembly time.

The SOLID GSX system allows for easy assembly and disassembly of entire inserts with equipment and wires in enclosures. In addition, HXS enclosures have a detachable back wall, which is very helpful for the assembly and wiring of a larger, more complex set of enclosures.

Detailed instructions describe in detail the method of mounting the equipment, and dedicated covers with cut-outs and mounting plates consisting holes for a specific type of equipment allow you to save the time necessary to designate the installation position.