Industry 4.0 at ETI

Industry 4.0 was a new term a few years ago, but nowadays it is seen as normal, which is also the case at ETI. There are many answers to the question of what Industry 4.0 actually means as well as how individual companies experience and integrate it into their processes.

| Jure Ferk |

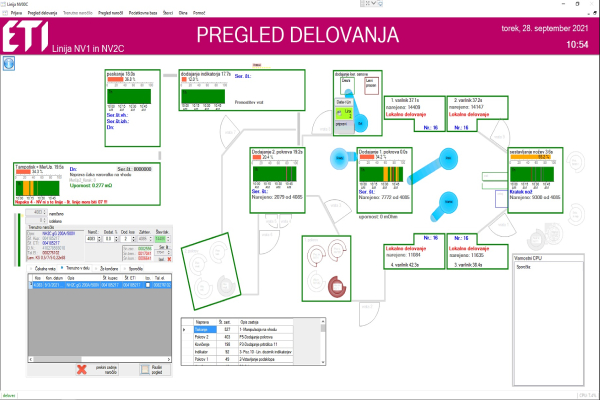

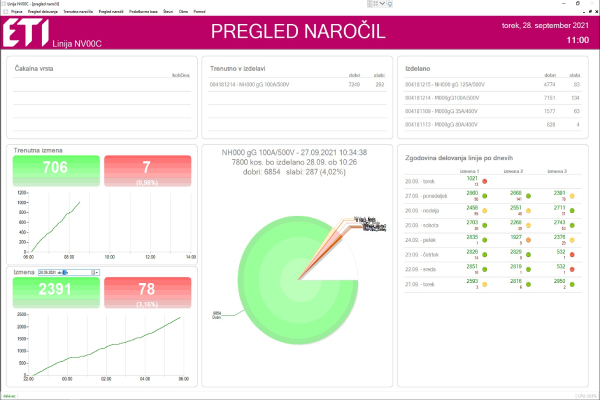

ETI started talking more concretely about Industry 4.0 as we know it today in 2016, when we participated in an expert economic delegation meeting in Germany, where energy efficiency and Industry 4.0 were the main topics of the event. Based on the information and good practices we gathered, we set out our objectives, which were updated and modified as necessary over time. One of the key objectives was to capture data from the machines, devices and production processes themselves and to further process it into meaningful and useful content. However, the capture of the data itself is key to all the steps forward, with the primary concern being to ensure the reliability of the data captured as well as the knowledge of the data content itself. This is how data capture is done today throughout production, from the simplest to the most extensive and complex data.

Today, we can say that we have succeeded very well in this key objective, among others, as the automatically generated OEE report is one of the key tools for decision-making and problem-solving in manufacturing.

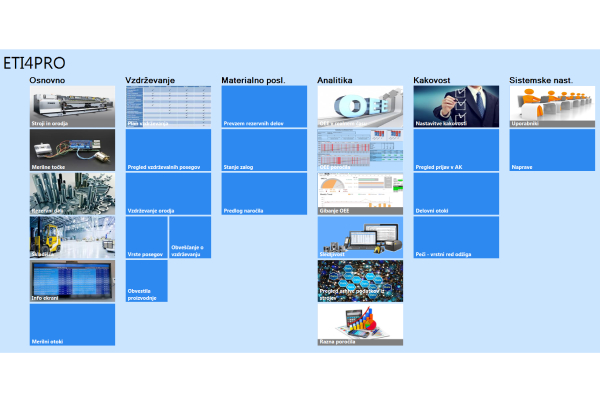

At ETI, we also perceive Industry 4.0 as much broader than just data capture and processing, because during this time we have developed, among other things, the ETI4pro platform, a software interface for monitoring the technical availability of machines and devices, an interface for the graphical display of machine stoppages and faults and an application for the control and management of lines or individual devices with the ability to connect to the Infor system as well as for archiving of data for the purposes of traceability of products, the introduction of video instructions using the Rewo application and the list goes on and on. What is essential to the story of Industry 4.0 at ETI is the fact that, in principle, all solutions have been developed and implemented on the basis of identifying needs and, secondly, that new solutions are being developed and implemented all the time. A very good practice is the creation of a lean office department, which, among other things, acts as a link between all other departments in order to achieve higher productivity, which is, after all, one of the key objectives of Industry 4.0.

|  |

But the whole story should not forget the other departments, each contributing in its own area to the achievement of the objectives and vision. Industry 4.0 has therefore existed at ETI for some time and is constantly being added to and developed. And what will it be like in ETI in a few years' time? We don't know; we might even call it Industry 5.0, as some articles are already saying. But we can say with certainty that it will definitely be different, because the vision is definitely focused on increasing paperless processes, introducing artificial intelligence and ultimately strengthening the link between production and other business processes within the ERP or Infor system.