Zinc: The Industrial Shield with Growing Green Relevance

Zinc has been known for millennia, primarily as a component in brass, but isolating it in pure form took time. It wasn't until the 12th or 13th century in India that zinc was produced in significant quantities. In Europe, large-scale production only began centuries later. The industrial revolution propelled zinc into mainstream use, particularly in galvanization — coating iron and steel to prevent rust and extend product life.

Powering Protection: Zinc’s Rise Through Industry

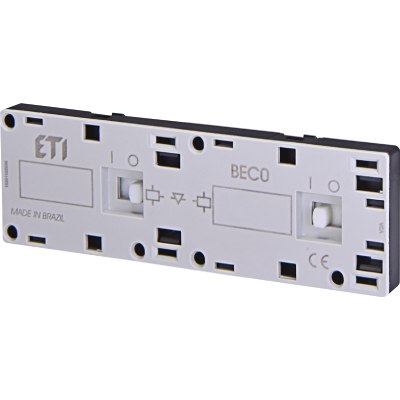

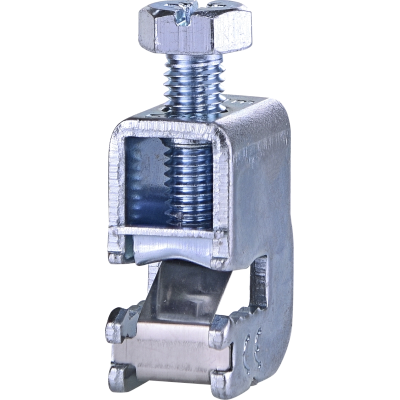

With its strong anti-corrosion properties, zinc became an essential material in construction and manufacturing. Galvanized steel — steel coated with a layer of zinc — protects buildings, vehicles, and infrastructure from the elements. Zinc is also a key component in die-casting for automotive parts and in fertilizers for agriculture. Its widespread availability and durability made it one of the most widely used non-ferrous metals in the 20th century.

Demand Drivers: Clean Energy, Vehicles, and Batteries

Today, zinc is playing an increasingly important role in the clean energy transition. According to the International Zinc Association, global demand for zinc is expected to increase by nearly 700,000 tons annually by 2030. This growth is largely driven by its applications in solar energy (550,000 tons), wind power (50,000 tons), and battery technology (45,000 tons). Zinc-air and zinc-ion batteries are being explored as lower-cost, safer, and more sustainable alternatives to lithium-ion batteries, especially for grid storage. Another 100,000 tons of zinc demand could come from the automotive sector. In countries like India and China, where galvanized steel use in vehicles is still below global averages, demand is projected to rise as these markets mature. Zinc’s role in corrosion protection ensures the longevity and safety of EV components and vehicle structures.

Supply Outlook: Challenges and Long-Term Stability

Zinc production has faced some short-term headwinds. According to Wood Mackenzie, zinc mine output declined again in 2024 — the fourth drop in five years — bringing global production to its lowest level since 2010. This decline reflects underinvestment, geopolitical risks, and the closure of older mines. However, long-term supply remains secure. A 2023 study published in Resources, Conservation & Recycling Advances estimates that current known reserves of zinc range from 25 to 67 billion tons — enough to meet global demand well beyond 2050. Importantly, improvements in recycling could allow up to 45% of zinc needs to be met by secondary sources by mid-century.

Securing Zinc for a Greener Future

As a durable, widely available, and recyclable metal, zinc is well-positioned to support a low-carbon future. Its use in protective coatings, energy infrastructure, and battery technologies makes it an unsung hero of sustainable industry. But to maintain supply stability and reduce environmental impact, greater investment in recycling, exploration, and innovation will be needed. With smart strategy and sustainable practices, zinc will continue to protect not only our buildings and vehicles — but our path to a greener tomorrow.